Delicate Substrate Handling

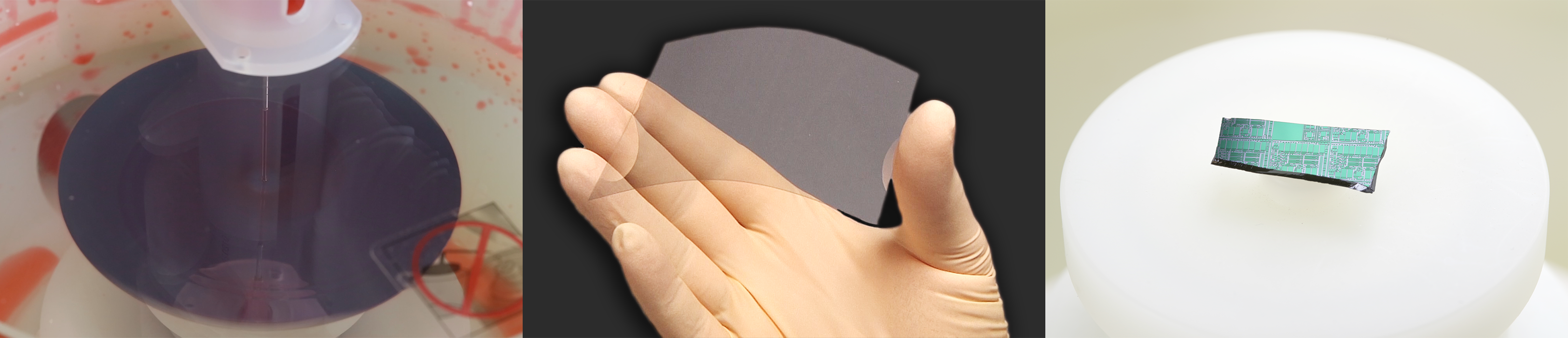

The range of substrate materials requiring accurate spin coated thin film depositions is growing.

From standard Si wafers through germanium, gallium arsenide, quartz, sapphire, and diamond. These materials tend to be brittle and can be damaged through rough handling.

Additionally, with the use of post process thinning, substrate thickness can range from a SEMI standard ~725µm, down to 200µm, 175µm, and even as little as 50µm.

Flexible substrates such as plastics, polymers, and metal foils may not be brittle, but they do require careful handling, and the correct type of chuck, to achieve successful coating.

Chuck Solutions

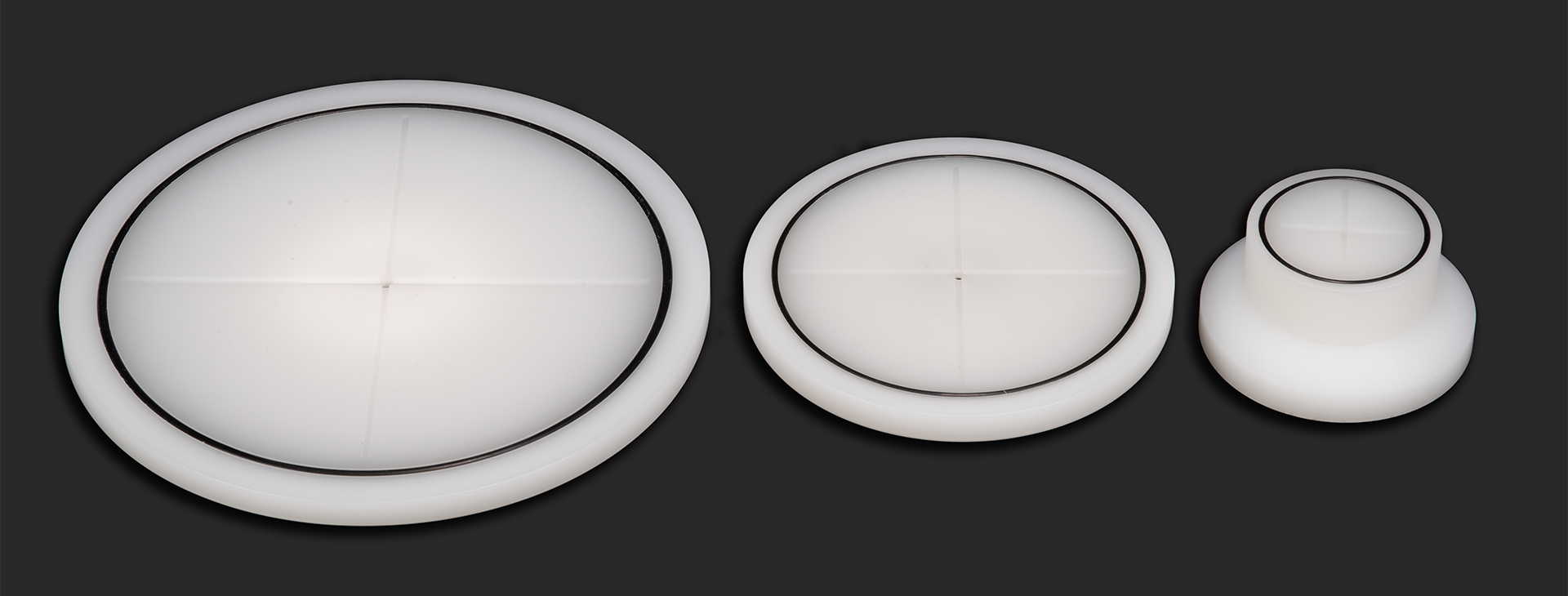

Standard Vacuum Chucks

Laurell has a large range of standard vacuum chucks. Most people are familiar with vacuum chucks that have a cross, scroll, or ring pattern of grooves that allow vacuum to be applied across the whole surface of the substrate. We use a cross and outer O-ring to seal the vacuum chuck face. The O-ring ensures a vacuum seal and allows larger, heavier, substrates to be held securely at higher speeds and with faster acceleration.

In general, materials >200µm thickness can be safely held on a standard vacuum chuck.

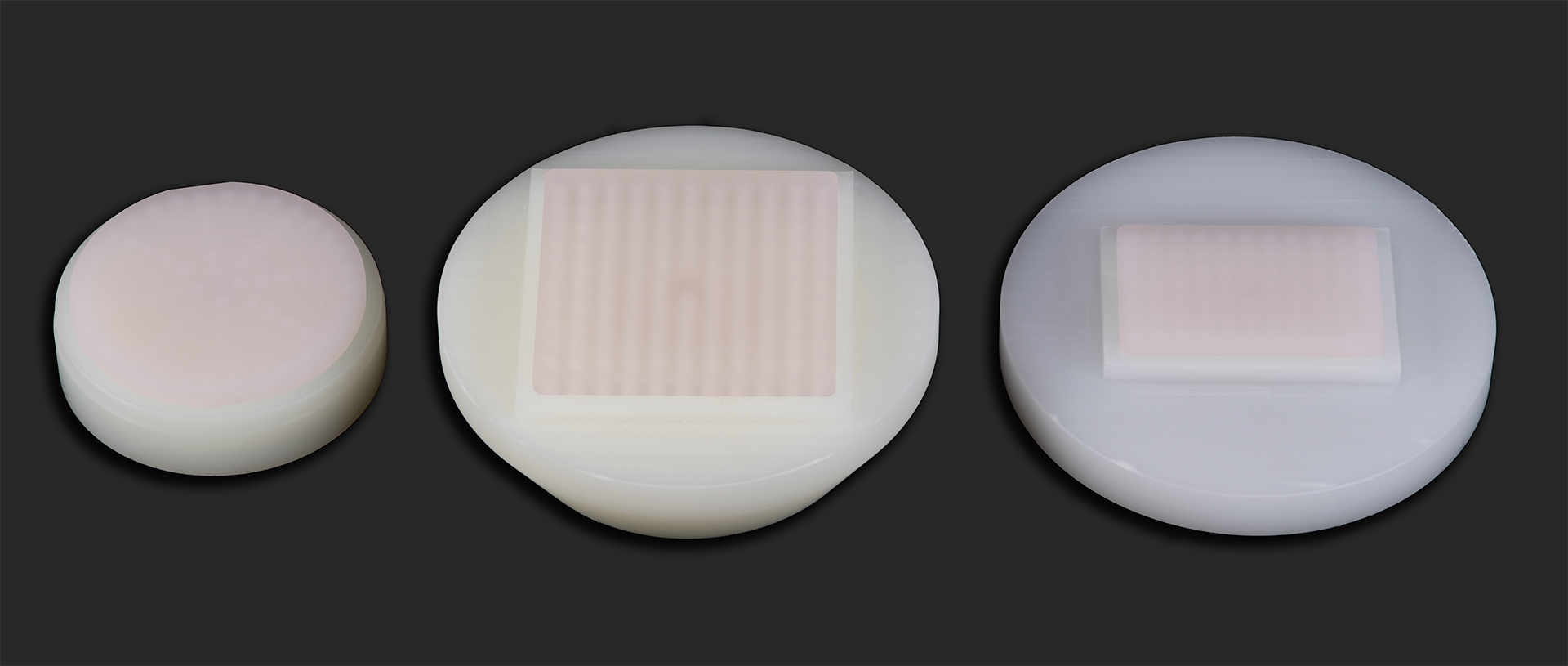

High Porosity Chucks

Thinner, or more brittle substrates can be safely held and processed on a high porosity chuck where vacuum is evenly distributed across a flat surface.

For non-standard substrates, the vacuum stage of a High Porosity chuck can be custom made to fit a particular shape, allowing a secure vacuum hold and improving coating results.

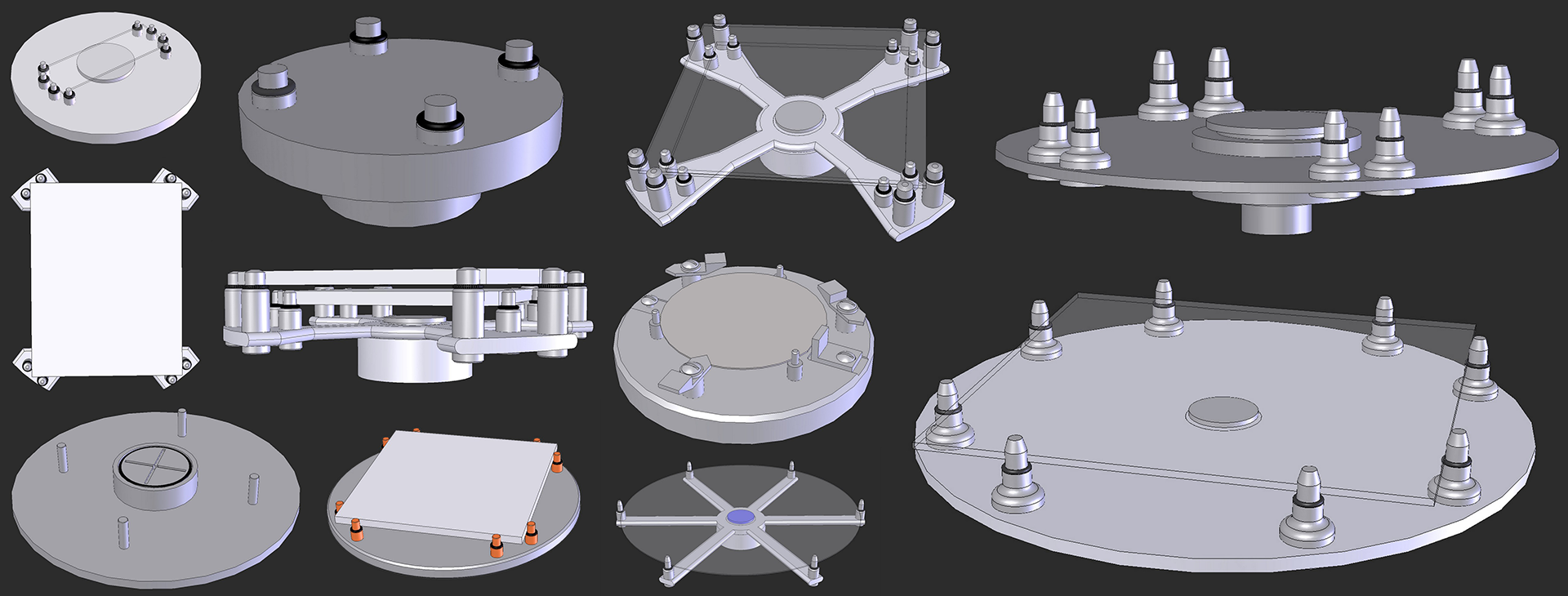

Specialized chucks

Our experience allows us to respond to customers unique problems with a custom solution. Processing substrates while they are still attached to a dicing frame is possible. We have created holding solutions for substrates with back-side features and a narrow safe contact patch. Whatever your substrate may be, we look forward to helping you achieve your best possible results.

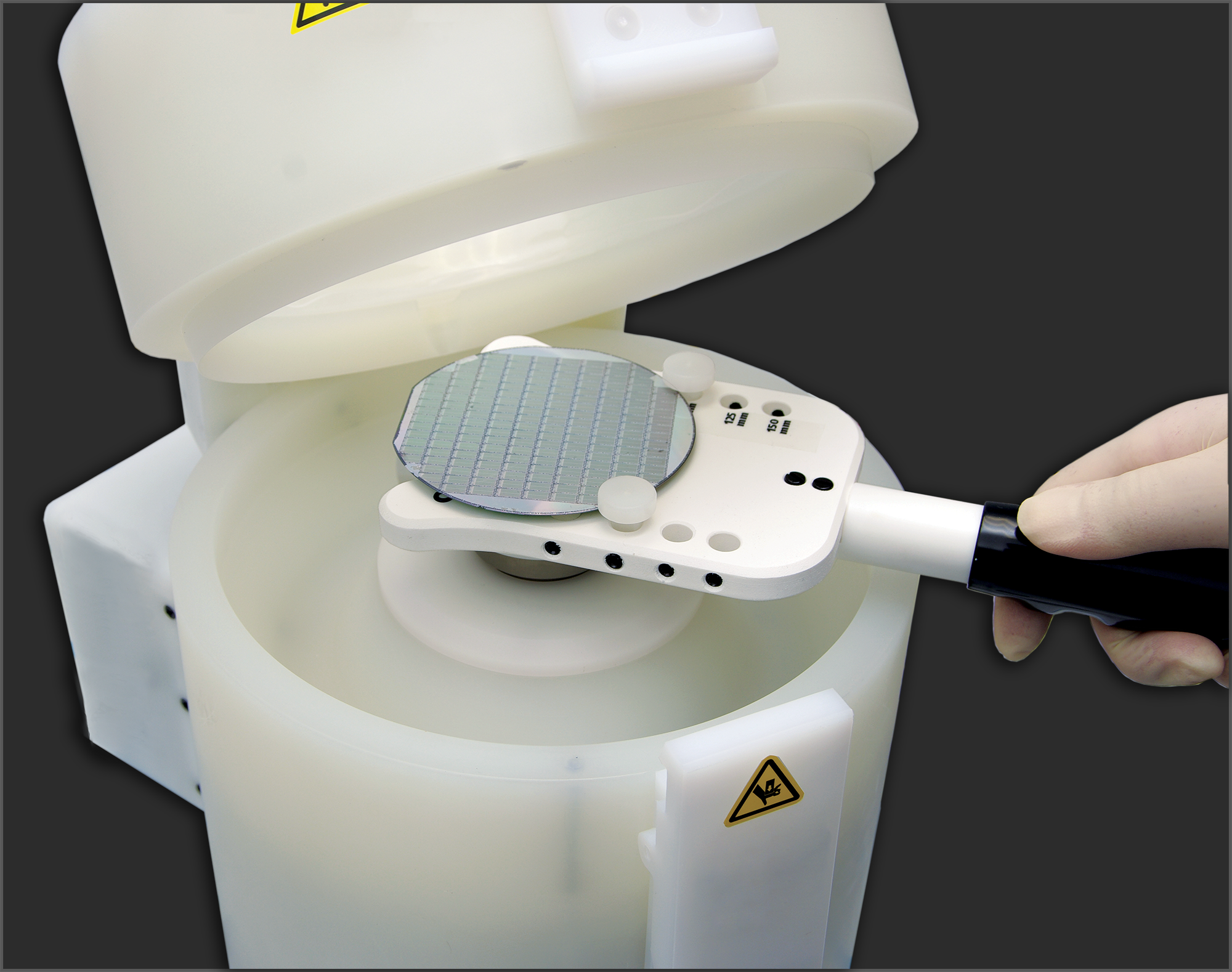

Easy Access

With a process chamber that lifts away from the housing, Laurell Technologies spin processors give you easy access to the chuck and substrate allowing you to safely and conveniently load and unload your substrates.

Lifetime Process Support

Every Laurell Technologies customer receives lifetime process support for as long as they have our spin processor. Complete a process support request to take advantage of our experience.