Spin Coating 101

What is Spin Coating?

... Spin Coating is the act of dispensing a chemical onto a rotating substrate at some spin speed(s) for some period of time which will result in a film of some thickness.

Since 1985, Laurell Technologies has dedicated our entire efforts to providing equipment that allows our customers to do this, as efficiently, accurately, and safely as possible.

Before Coating Your First Wafer

A successful result requires that you pay attention to the following:

- Environmental conditions including temperature, humidity, airborne particulates etc.

- Quality of your consumables, is your chemistry fresh?

- Cleanliness of your substrate, and equipment. Starting with a contaminated substrate ruins your process before it begins

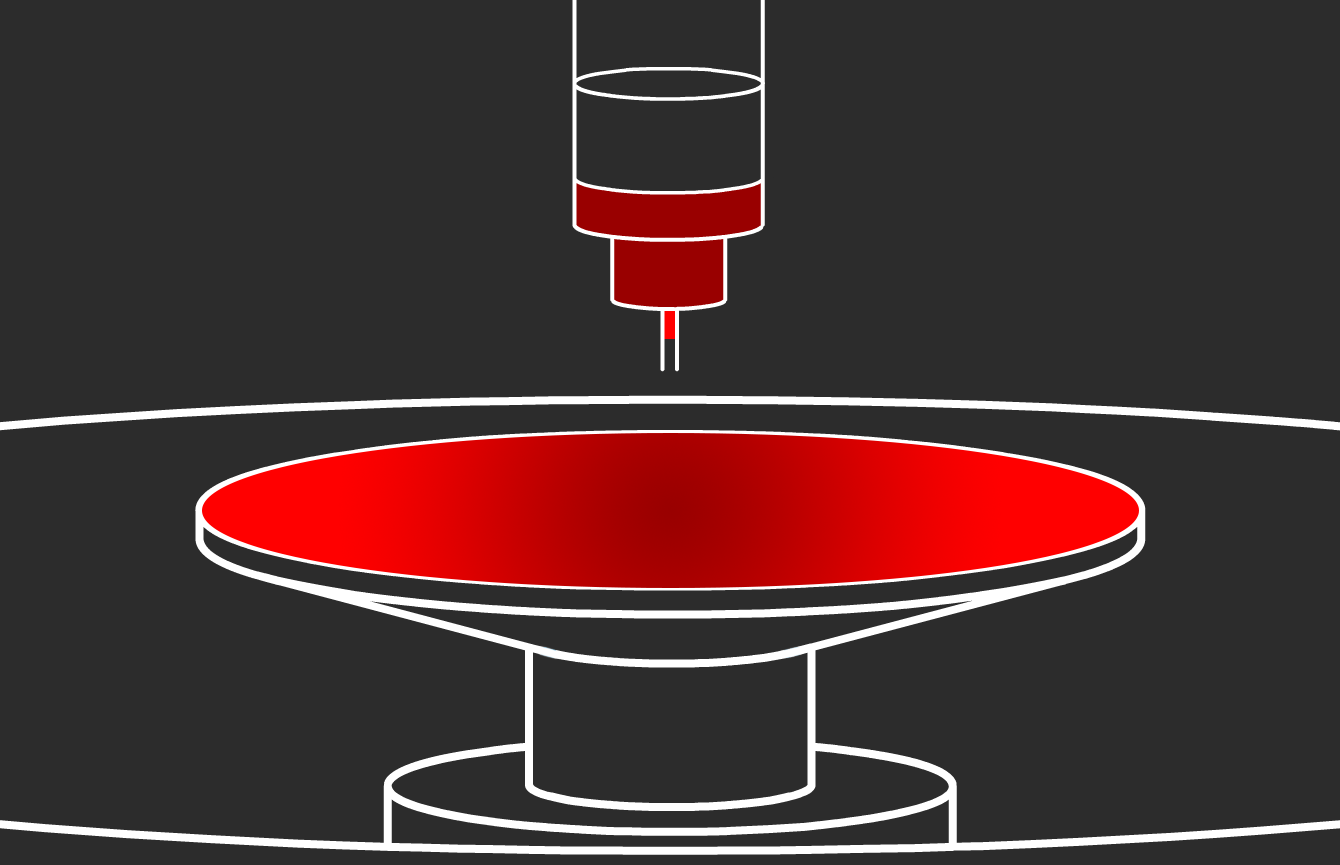

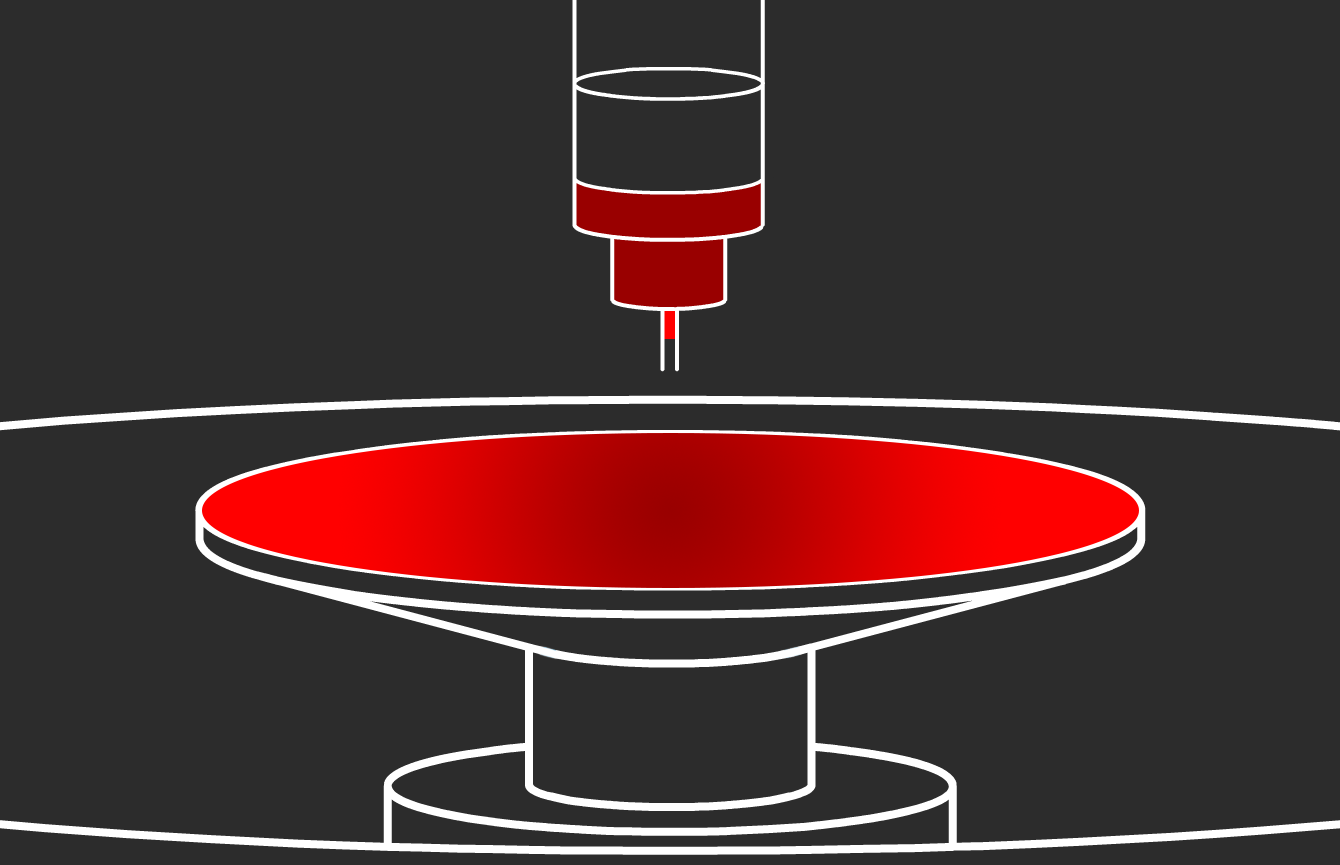

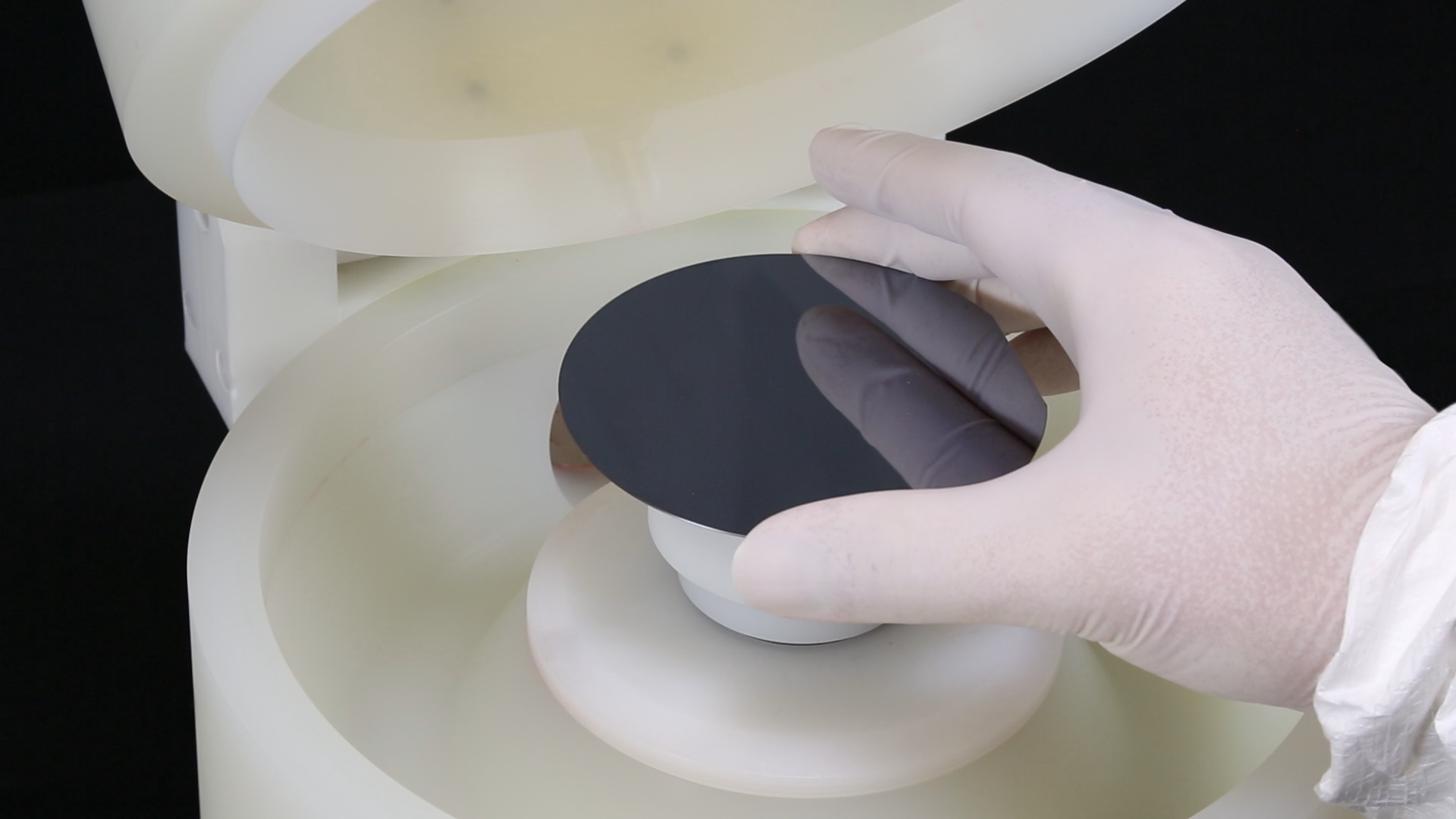

- For coating applications you will be using a vacuum chuck to hold the substrate while depositing your chemistry. To secure the substrate, and allow the highest spin speeds and acceleration, it must completely cover the face of the chuck and create a vacuum seal. Laurell produces a huge range of chucks that makes picking the right option simple.

- Once you have the chuck, ensuring that the substrate is correctly centered minimises instability. For SEMI standard and round wafers Laurell Technologies has a range of standard alignment tools with custom designed and engineered options available.

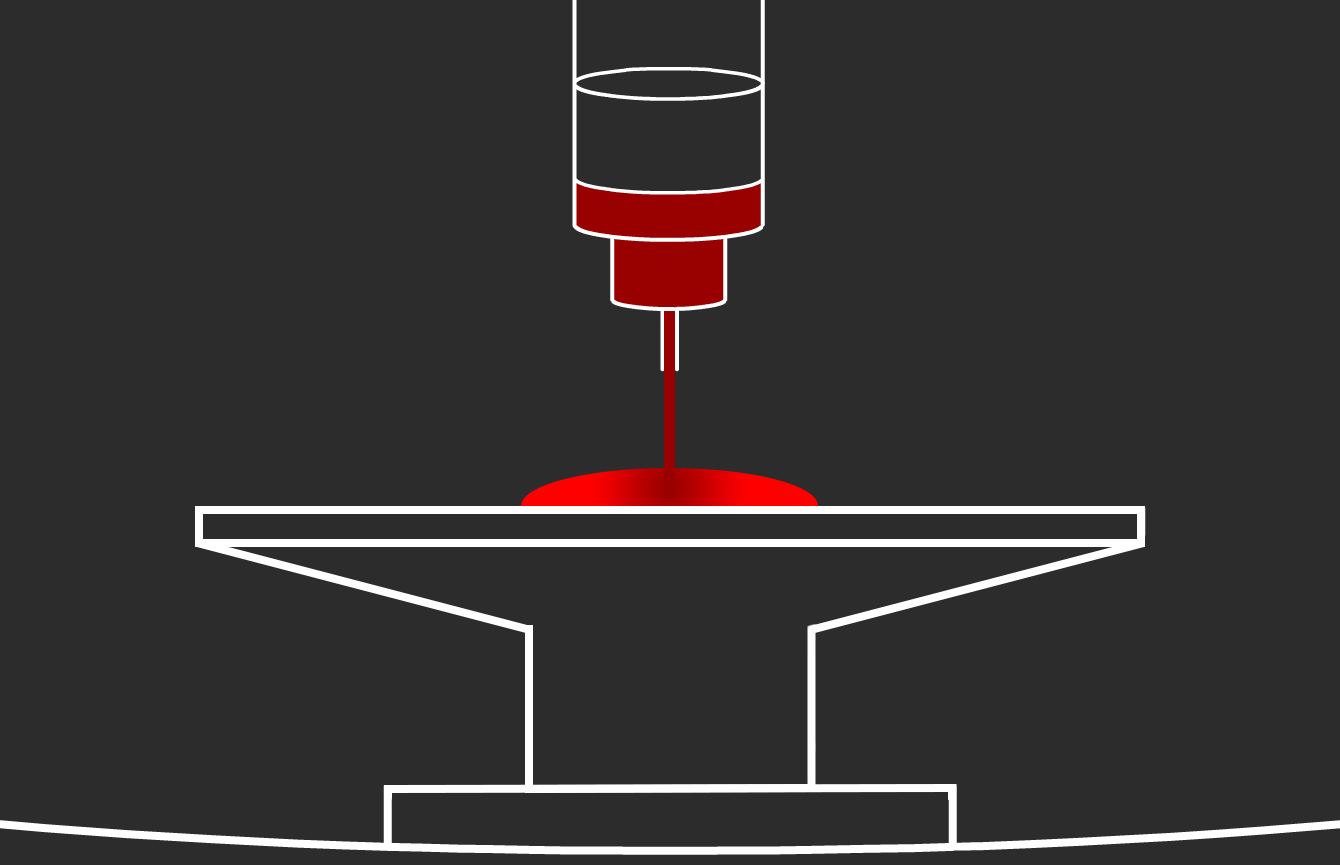

- How you dispense the material onto the substrate will have an effect on the quality of your coating. Simple manual dispense via pipette can be effective. We recommend using a syringe and our syringe holder for a consistent dispense.

- For the most consistent and accurate dispense Laurell Technologies can provide several automatic dispense options. The center mounted UD-3, the off-center UD-3b, and the Single Shot Dispense are all integrated with the system controller and are fully programmable.

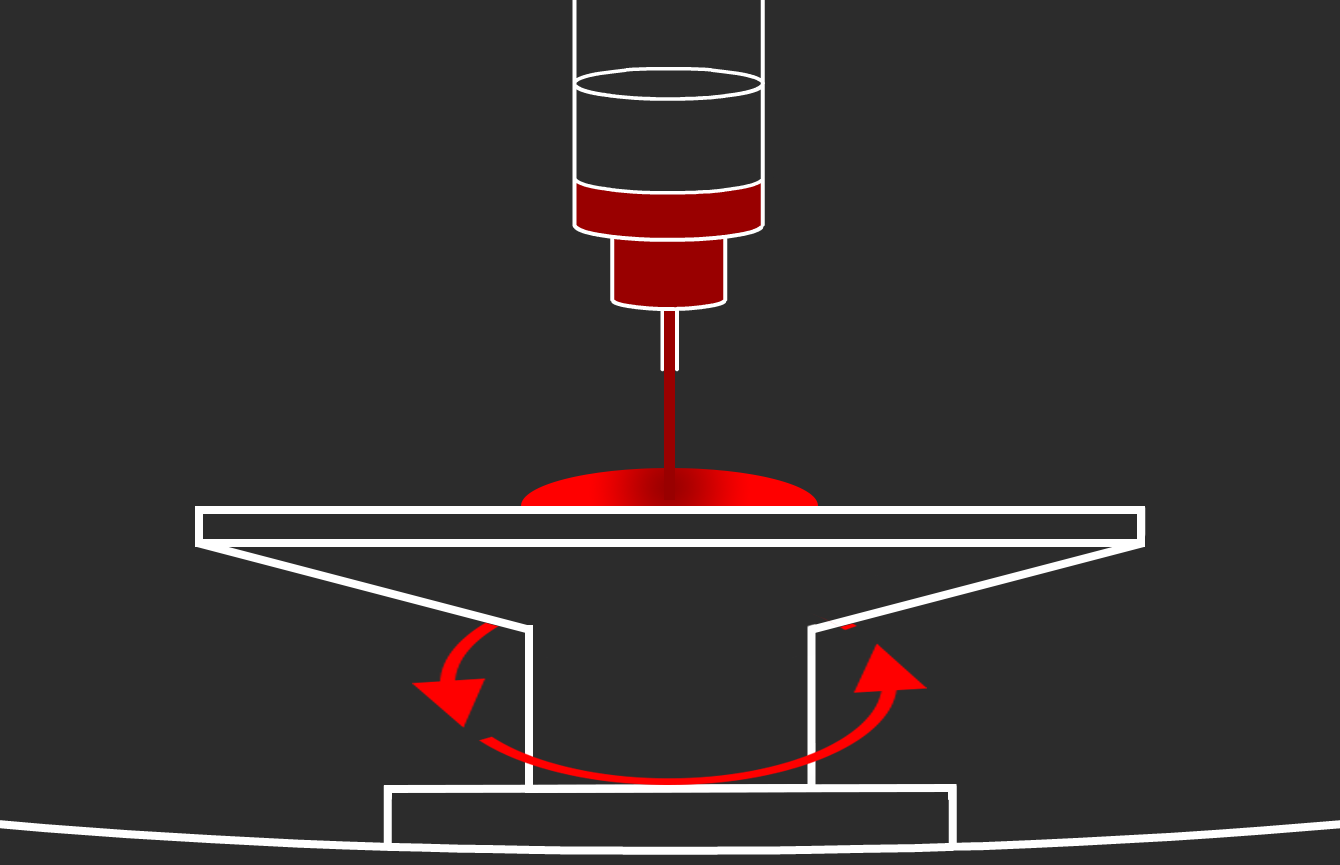

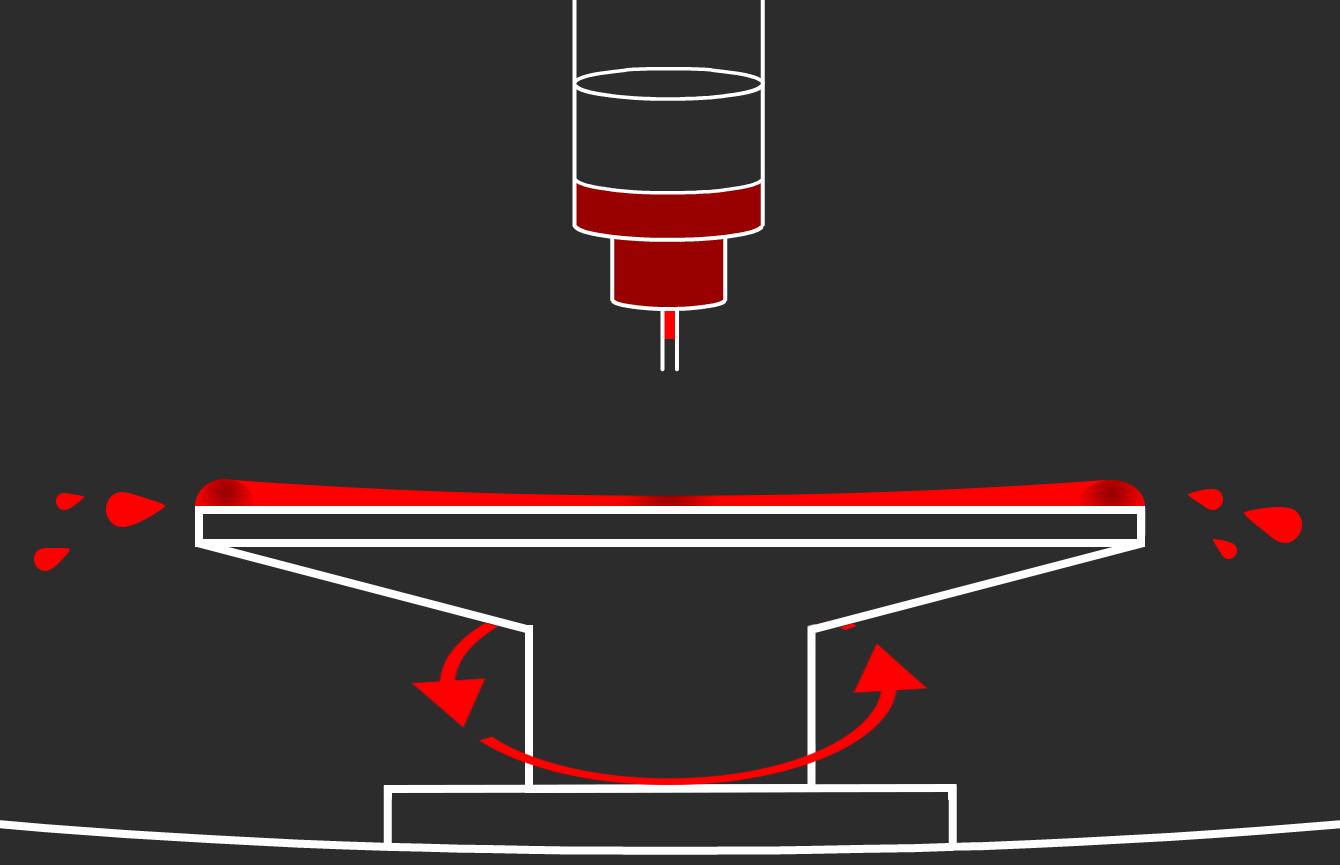

- Deposit your chemistry at the center of your substrate. The puddle should cover an area up to half the diameter of the substrate.

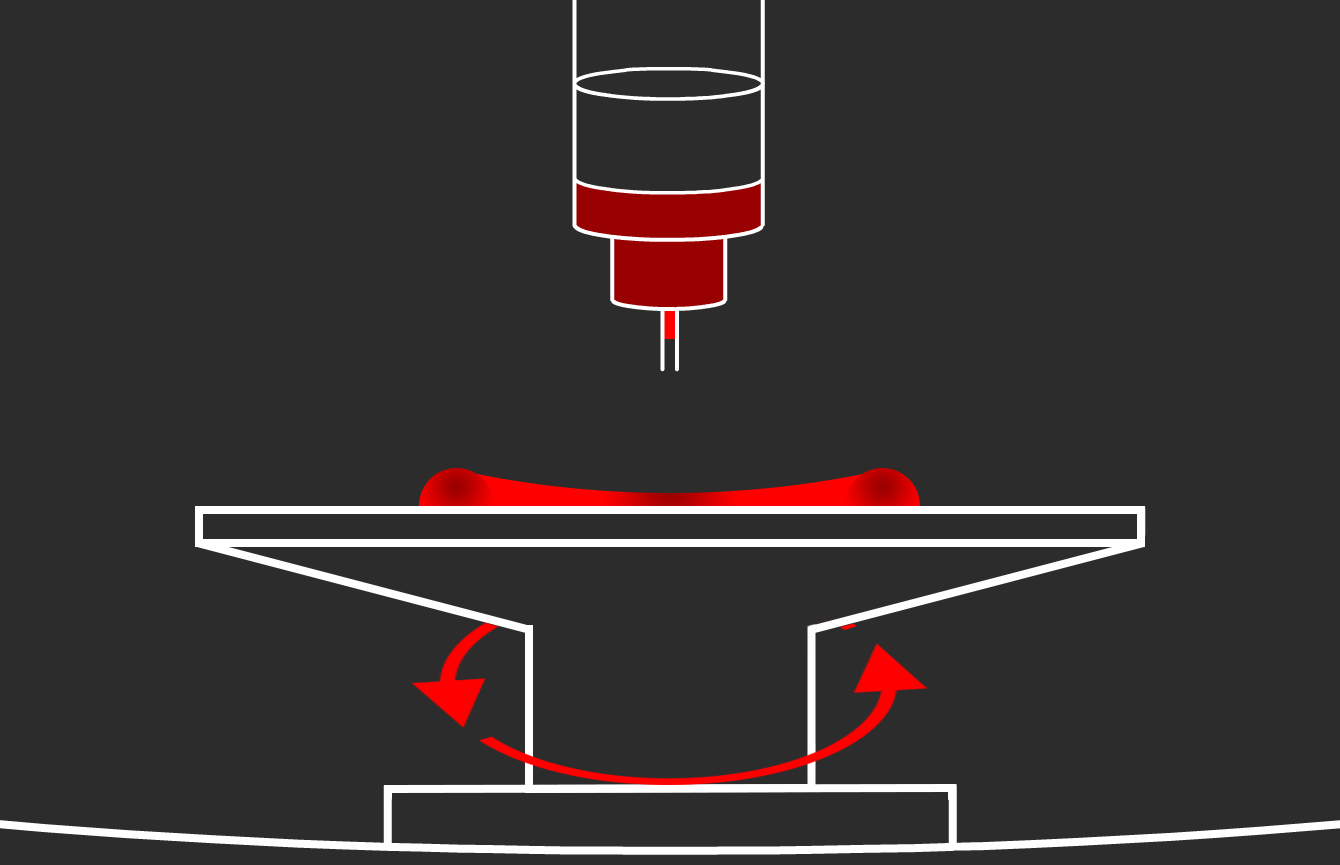

- Start the spin coater. The centrifugal force will spread the material across the surface of the substrate

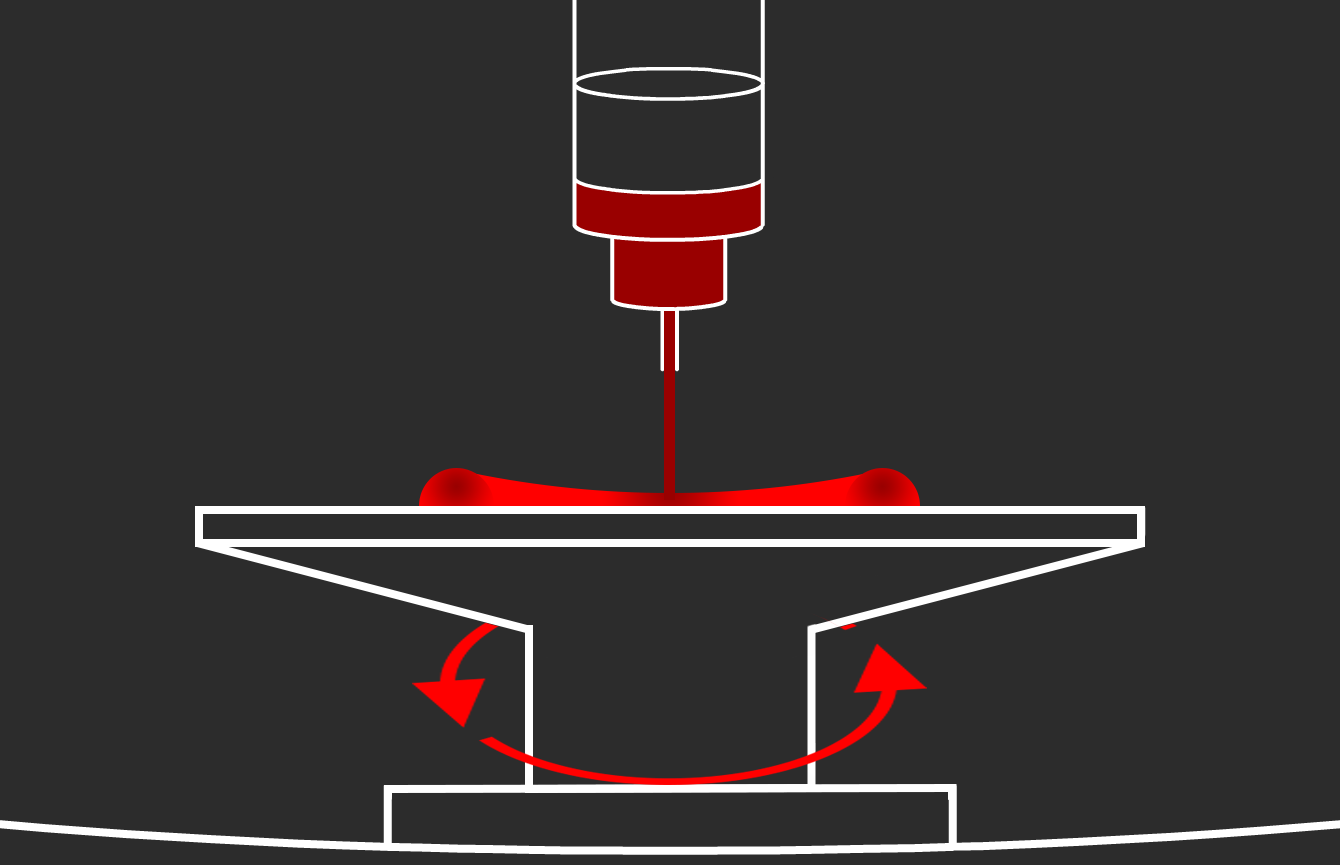

- Excess chemistry will be cast off the substrate.

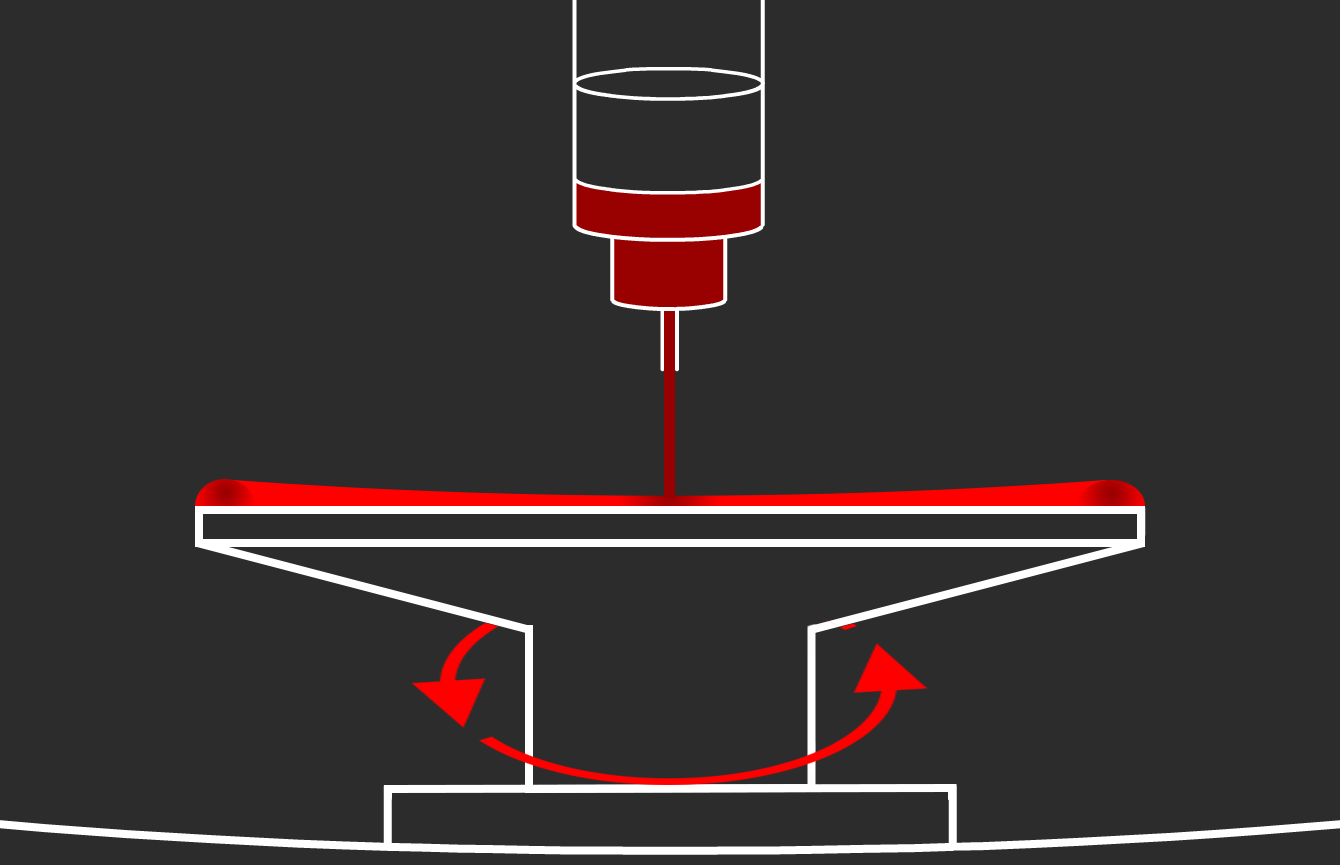

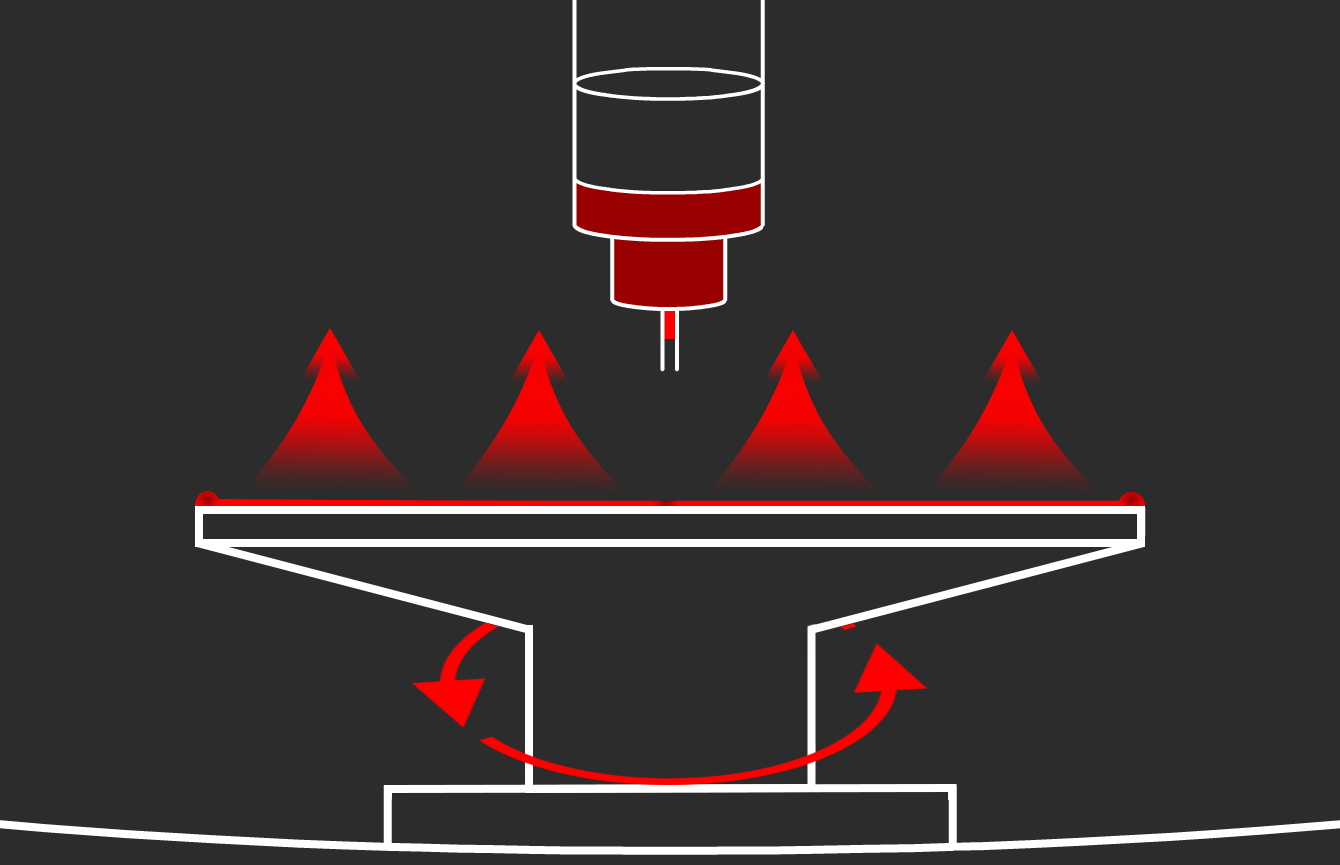

- As the substrate is spun the solvents in the chemistry evaporate and the final film thickness is a function of several factors with the final spin speed, and the material viscosity being the most significant.

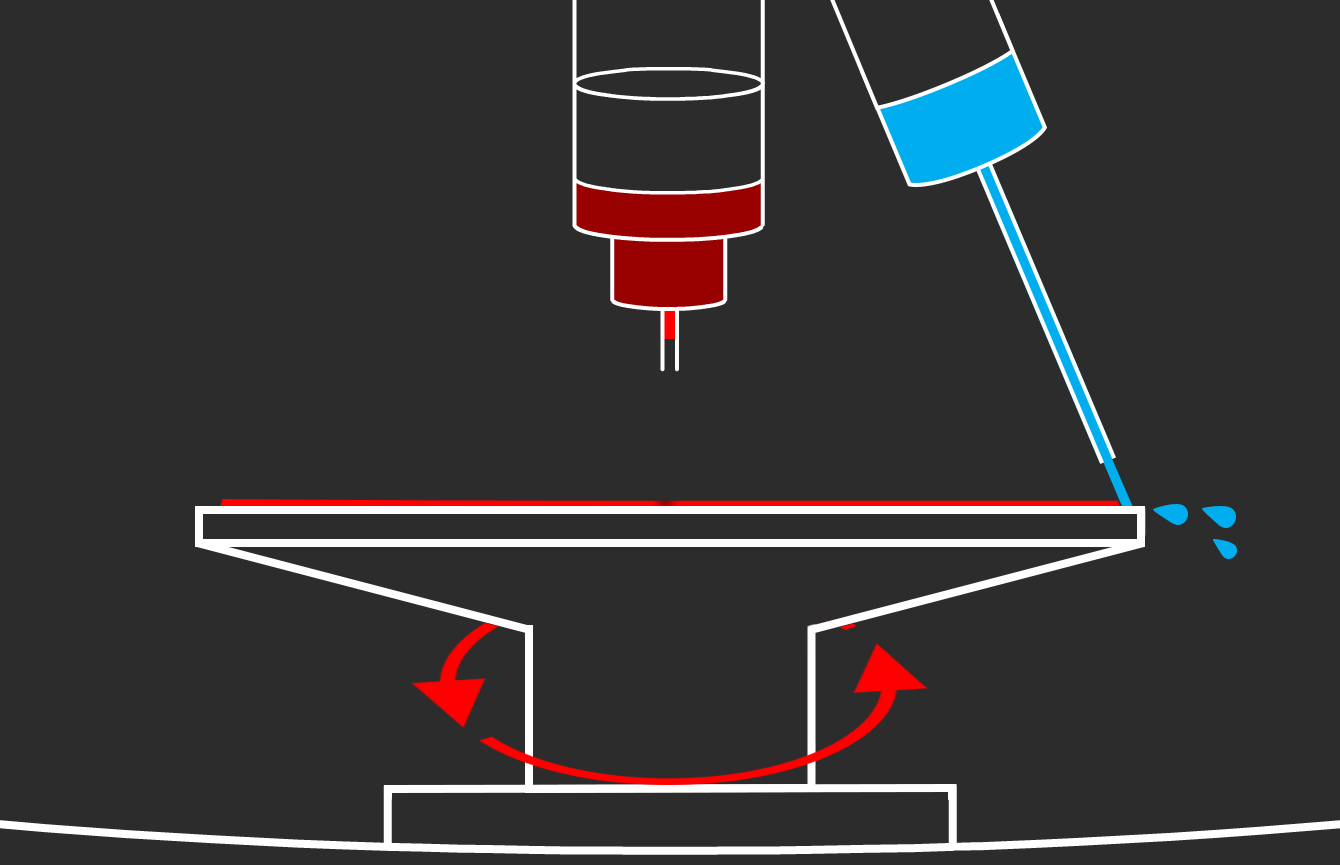

- As part of the process a bead can be formed at the edge of the substrate. This edge bead can interfere with further processing. Removing the edge bead can be done with a controlled stream of solvent and is best done as part of the coating process.

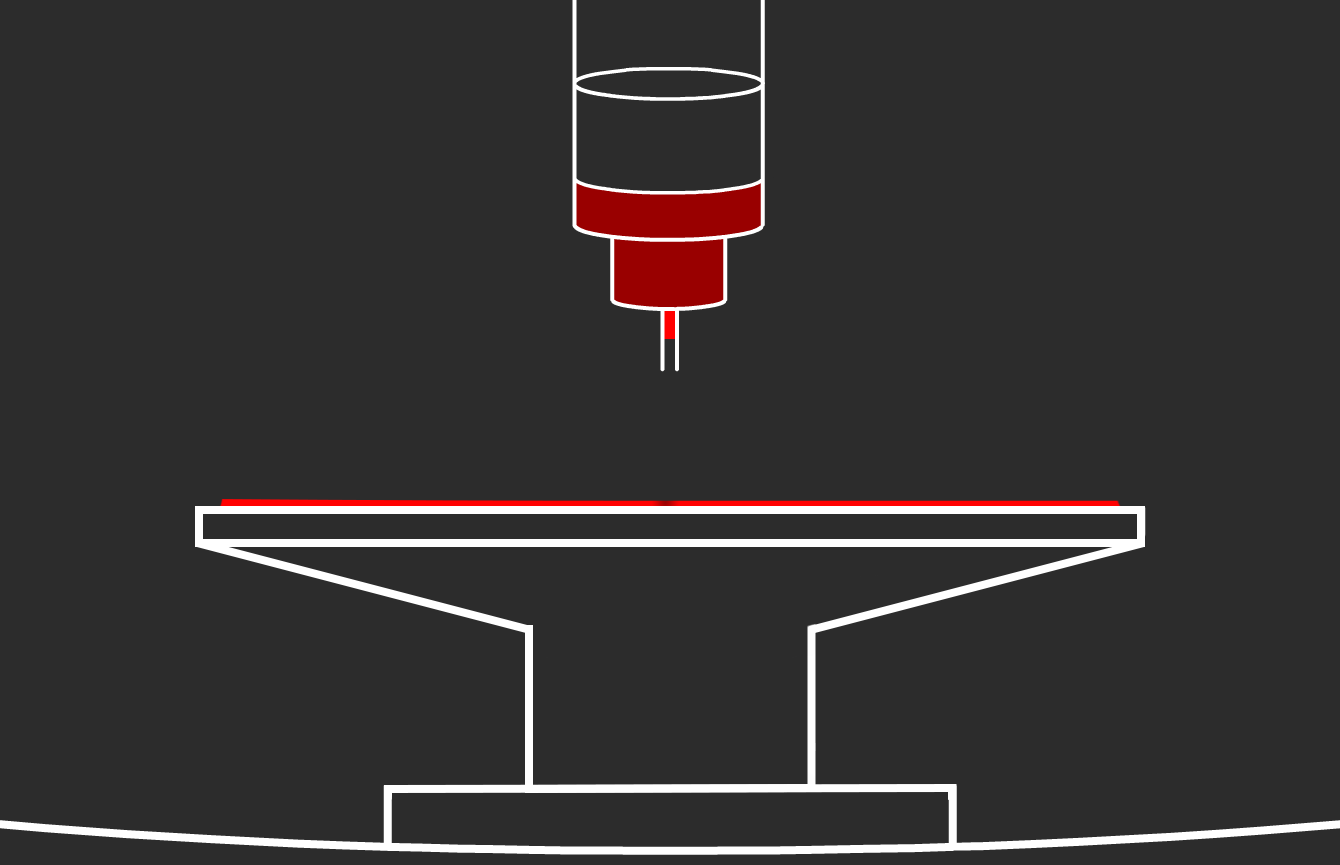

- Once the coating is set the process is complete. With accurate characterization of the film you can adjust your process to obtain the results required.

- Dynamic dispense differs from static dispense in that you will dispense your chemistry onto an already rotating substrate.

- The spreading begins as soon as the chemistry contacts the substrate.

- You continue to dispense until the chemistry reaches the edge of the spinning substrate.

- The process from this point is the same as static dispense. It has been our general experience that a dynamic dispense gives better and more consistent coating results than static dispense.

Spin Coating 101

Mounting the substrate

Static Dispense Coating

Dynamic Dispense Coating