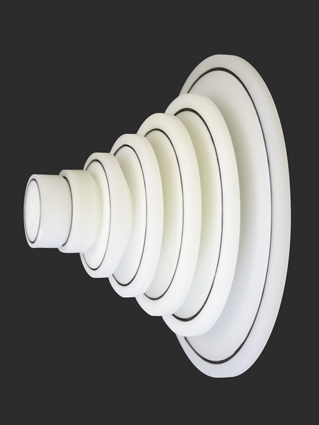

Low Profile

These low-profile, O-ring-sealed vacuum chucks are designed to secure substrates very firmly, without deflection, and can operate at very high rotational speed. This simple, balanced, low mass design allows for instantaneous direction change with precise acceleration and deceleration control.

Convenient and affordable fragment adapters are available to accommodate 3 to 50 mm pieces.

See the wafer alignment tool in action below:

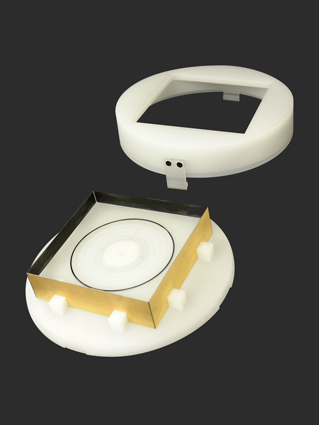

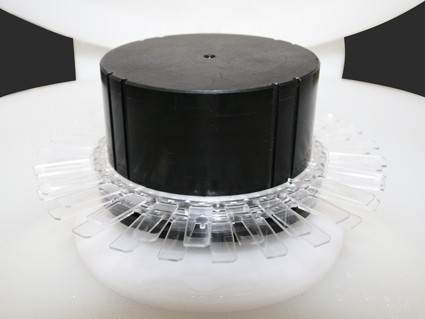

Fragment Adapters

Always have the right size holder with an O-ring seal to maintain vacuum grip and at the same time cushion your substrate. Slides conveniently over the standard Ø1.75" (~45 mm) chuck.

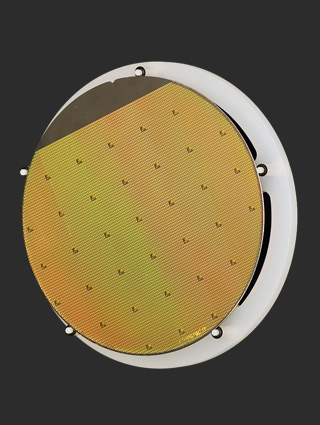

Embedded Vacuum

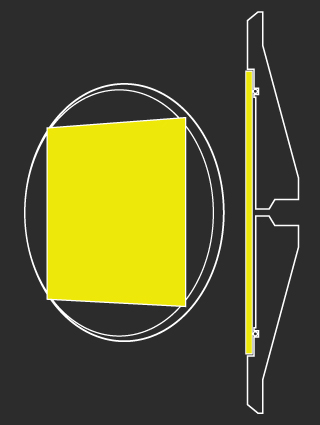

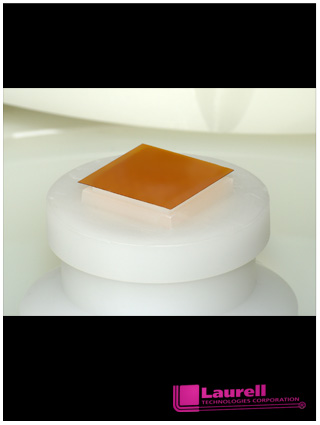

Embedding substrates into the chuck's face is done for two reasons: alignment and uniformity, or possibly both reasons. Thick, round substrates are centered precisely every time, making it virtually impossible to eject during rotation, even if vacuum hold-down fails. A thick, square substrate coating is uniform, even at the edges and corners, being fooled into thinking it is round like the chuck, because it is in such close proximity.

Note: minimum thickness is 0.5 mm. Size, tolerance, length, and width must be within ± 0.005" (0.127 mm) — larger will not fit, smaller may not be centered. Several chucks may be required for wide ranges.

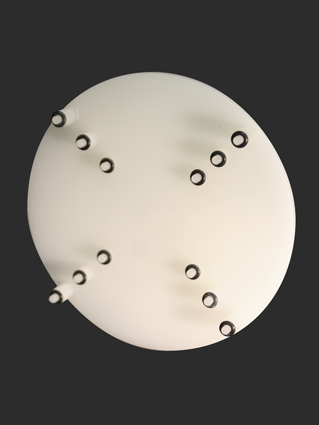

High Porosity Vacuum

Flimsy films or foils which cannot support themselves, thermally sensitive optical materials, and thin fragile materials can be securely held with vacuum while being processed. Laurell invented this technology 20 years ago and has many different technologies and porous materials to choose from. No matter what your substrate shape or holding problem is, we likely have an engineered solution, or know where to start to help achieve your goals.

Note: minimum practical size is 10 mm to 7" X 7" (180 mm X 180 mm) and the current technology requires a greater vacuum volume than do our other O-ring sealed chucks. This type of chuck is NOT recommended for use with Laurell's IV-PVG, because the design requires high vacuum volume (consult your salesperson before choosing this option).

Suction Cup

- Conformal, Mark-Free Suction-Cup Chuck

- Ideal for polycarbonate lenses — will not damage your sensitive material!

- If scratch-free, two-sided coating is your problem, this chuck is the answer.

- Available in many sizes — same chuck, many suction cups...

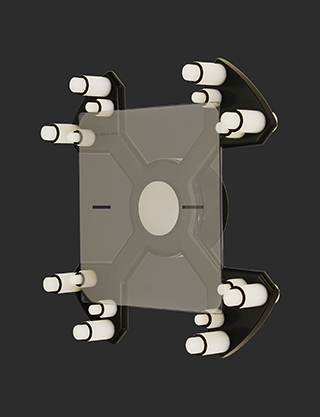

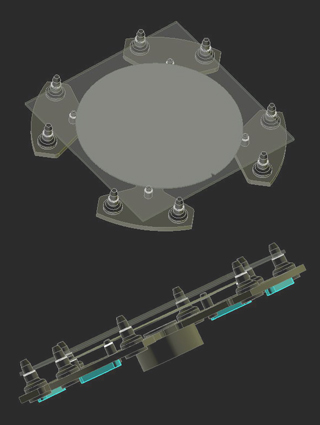

Low Contact

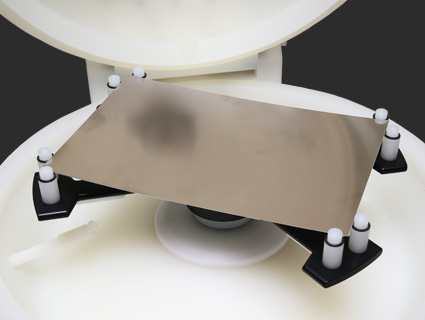

Closed-Bottom Mechanical Hold

If you can't use vacuum hold-down, we have a wide variety of edge-grip chucks with the absolute minimum back-side contact. Multiple size substrates can be accommodated on the holder shown.

Open Back-Side Rinse (BSR)

If you do simultaneous front and back-side processing, choose our open-bottom edge-grip chucks. Multiple size substrates can also be accommodated on the holder, but the amount is limited by turbulence caused by too many pins.

Chucks for Special Applications

We have efficiently engineered and built thousands of successful custom chucks. Please feel free to give us your holding problem

Laurell Chucks FAQ

What makes Laurell spin coater chucks superior?

A. Laurell designs and manufactures each chuck specifically for its intended use. Our application-specific chucks are also easy to change and quite affordable. Many convenient slide-on adapters are also available.

How can I make sure my wafer is centered precisely in the center of the chuck?

A. Laurell has several wafer alignment tools for round substrates. Thin square or rectangular plates are aligned in many different ways; your salesperson can explain.

Can I make my own chuck(s)? What about proprietary materials and fixtures?

A. Laurell chucks run best on Laurell systems. But if someone has a design they like better, we will make every effort to accommodate their wishes. If you allow us to design, manufacture, and test the safe operation of your design, we would be more than happy to sign an agreement protecting your Intellectual Property.

Can Laurell build chucks for other manufacturers' systems?

A. Our policy is not to enhance other manufacturers' equipment. Our competitors have tried to copy our designs for decades, but none have even come close to equalling our performance characteristics and safety advancements. We have been designing and building chucks since 1985 and have made hundreds of incremental enhancements! Yes, you need to purchase a Laurell spin coater to enjoy all the benefits we have accumulated.